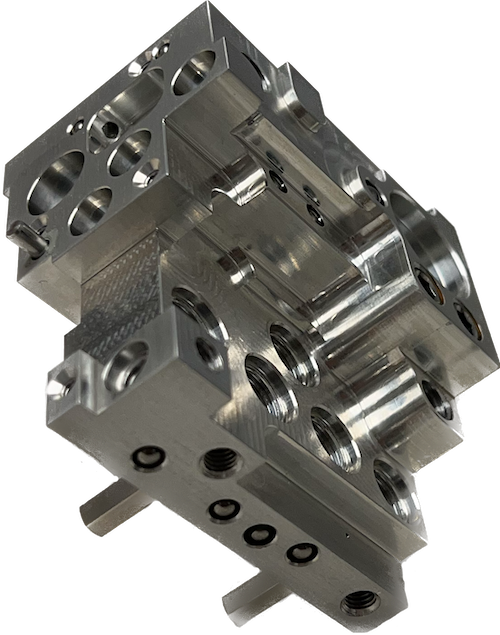

Manufacturing processes

P&C has a comprehensive range of engineering machinery and processes available. Our team of engineers also operate MASTERCAM & OneCNC CAD software.

We produce components in a variety of materials from plastics to the harder stainless steels.

Two automatic bandsaws for sectioning of bar or bundle stock and a forklift assist in the day-to-day activities on-site. Other machines include manual mills, beadblaster, slotter and an ultra sonic cleaner.

CNC turning

We are equipped with fully flexible CNC turning centres which have automatic magazine bar feeds.

All machine programmes are computer stored against part and issue number to ensure minimal set-up times for repeat orders.

Our CNC turning capacity includes:

- 1 x Hyundai Hit CNC turning centre with live tooling - 65mm bar capacity, 250mm chuck diameter with a 12 station tool turret

- 8 x Hyundai Hit CNC turning centres - 65mm bar capacity 200mm chuck diameter with a 12 station tool turret

CNC milling

Our CNC Milling capability has been increased significantly with the acquisition of a Hurco VMX42SRTi 5-Axis machining centre.

Below is a list of the CNC machining centres we currently have. This list is not exhaustive as we are constantly updating our machines, so please get in touch with us if you have any queries.

- 1 x Hurco VMX42SRTi 5-Axis machining centre

- 1 x Haas Automation VF3-SSYT 5-Axis Machining Centre

- 4 x Haas Automation VF1-DSE machining centres

- 5 x Haas Automation VF2-DSE machining centres

- 2 x Haas Automation VF3-DSE machining centres

- 2 x Haas Automation VF3-SuperSpeeds machining centres

- 1 x Haas Automation VM2 machining centre

Production management

At P&C we offer a much more comprehensive service than just sub-contract manufacturing. Our specialist precision engineers work closely with customers to offer solutions they might need in their production chain, including:

- Consulting

- Design advice

- Prototyping

- Volume manufacture

- Full and sub-assembly

Get in touch to discuss your engineering needs.